To scale predictive maintenance across their Azure ecosystem, we deployed two Senior Data Scientists to design, build, and operationalize AI models within the client’s existing infrastructure, without disrupting ongoing operations.

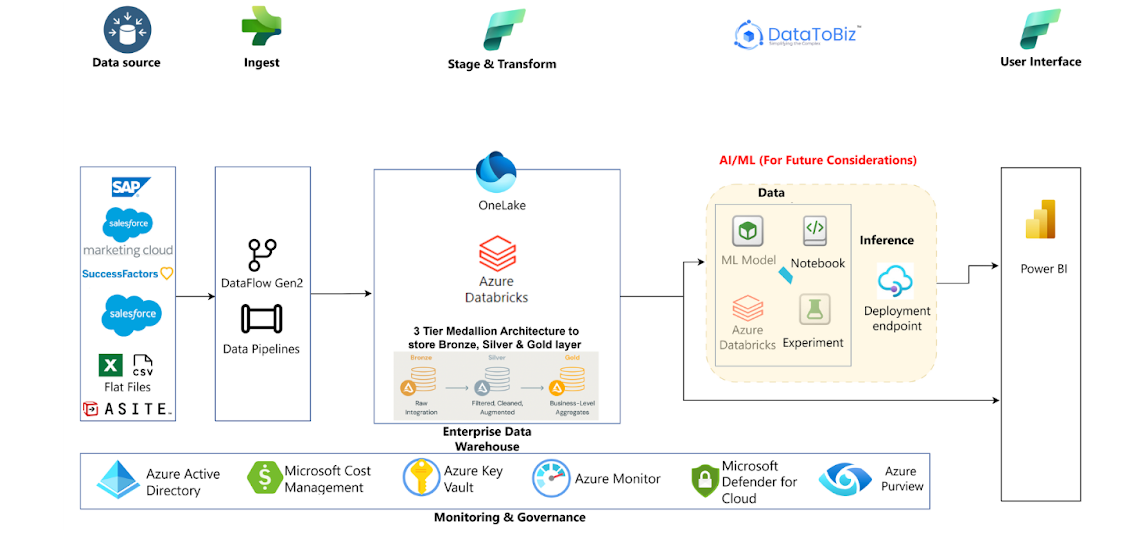

We used Azure Data Factory and Azure Event Hub to ingest high-volume IoT sensor data and maintenance logs into a centralized Azure Data Lake, built on a scalable, modular architecture to handle growing data loads.

Databricks with PySpark enabled distributed data preprocessing at scale. Models for anomaly detection and equipment failure prediction were developed and trained using Azure Machine Learning.

Models were deployed using Azure Synapse, Azure Functions, and Logic Apps to enable real-time inference.

Performance metrics, data drift, and anomaly patterns were tracked continuously through Azure Monitor, with automated alerts triggering retraining or escalation when needed.

To ensure long-term sustainability, we conducted hands-on training, shared detailed documentation, and hosted internal workshops.

All pipelines were built to meet POPIA compliance, with strict encryption protocols, role-based access control (RBAC), and secure data policies in place. Automated retraining workflows were implemented to keep models responsive and relevant over time.

To address the client’s need for a unified, automated ML lifecycle, our team of data engineers built a scalable MLOps platform on Azure.

Databricks with PySpark was used for data preprocessing and model training.

Model development, tuning, and deployment were automated using Azure Machine Learning.

Models were containerized and deployed on Azure Kubernetes Service (AKS) for scalable inference.

Azure Monitor and Application Insights tracked model performance and detected drift.

Automated alerts and retraining workflows helped maintain reliability and model freshness.

Supervised learning models powered failure prediction and anomaly detection.

Time-series analysis was used to improve accuracy in maintenance scheduling.

Power BI dashboards presented real-time asset health and key performance metrics.

Role-based access control (RBAC) ensured secure and structured data access.

Early fault detection models helped catch issues before they escalated, cutting unexpected failures by 50% and keeping operations running smoothly.

Automated alerts and insights optimized maintenance scheduling, improving efficiency by 35% and minimizing unnecessary servicing.

Real-time monitoring and alerts enabled field teams to respond 60% faster to potential issues, reducing average resolution time significantly.

By shifting to a proactive maintenance strategy, the client saw a 45% increase in asset life, reducing replacement costs and downtime.

Power BI dashboards provided live visibility into asset health, uptime, and fault trends, allowing operations teams to act on anomalies as they happened.

With skilled staff augmentation, the team was able to hit critical milestones faster and complete knowledge transfer without delays, boosting internal productivity.

All-in-all, our team of staffing experts helped the client take predictive maintenance from pilots to full-scale operations. With automated deployment, monitoring, and retraining in place, the client reduced downtime, improved asset reliability, and gave their teams the talent and tools to make faster, smarter maintenance decisions.

Energy, Utilities & Resources

Africa

Staff/Resource Augmentation

Briefly describe the challenges you’re facing, and we’ll offer relevant insights, resources, or a quote.

Business Development Head

Discussing Tailored Business Solutions

DataToBiz is a Data Science, AI, and BI Consulting Firm that helps Startups, SMBs and Enterprises achieve their future vision of sustainable growth.

DataToBiz is a Data Science, AI, and BI Consulting Firm that helps Startups, SMBs and Enterprises achieve their future vision of sustainable growth.